When using frameworks instead of solid beams, building materials can be used more efficiently. The timber is mainly subjected to tensile and compressive section forces parallel to the fibre, so that the advantages in terms of both strength and rigidity can be achieved. The efficiency of the connections at the junctions is crucial for cost-effectiveness. The structure can be optimised to the highest load level by the targeted use of hardwood.

Draft

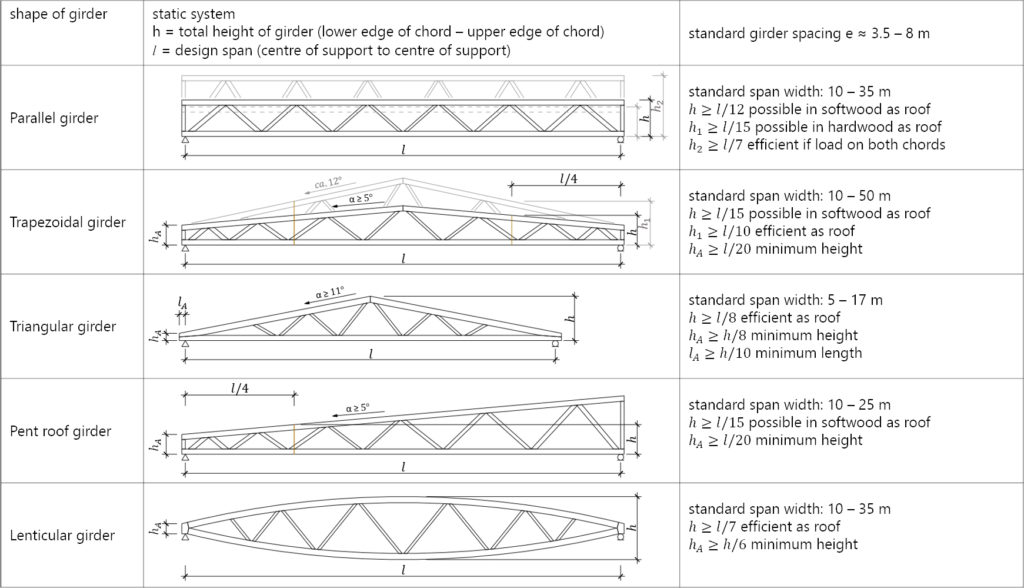

Forms of girders

The construction conditions are highly important in the selection of the optimal girder. We will be pleased to provide you with a non-binding consultation for a specific project. | Support

For a truss to be efficient and the standard static simplifications permissible, the beam height should be no more than 1/7 of the mean girder height (lower edge – upper edge).

Transport dimensions

A girder can be prefabricated in the factory provided the following dimensions are not exceeded:

Length: 35 m

Height: 5 m (transport width)

Weight: 20 tons

If larger components are required, please contact us well in advance.

Pre-dimensioning

Joiners

The following Information is restricted to two strut connectors per Joint.

Joint rigidity for struts

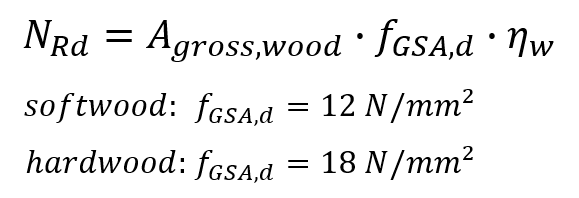

For timber frames in softwood, rigidity to a design level of 12 N/mm² is recommended for the pre-dimensioning. This stress refers to the gross cross section of the wood. Naturally, humidity and load duration with the usual coefficients must also be taken into account. A view of the measurement values according to Norm SIA 265 immediately shows that at least GL28h is required for such large connected loads, so as to be able to provide verification in net cross section. In addition, the cross sectional dimensions are to be adjusted to the construction’s anchor spacing. The following preferred dimensions result, depending on the rod diameter required:

M16 → strut widths [mm]: 120, 200, 280

M20 → strut widths [mm]: 160, 240, 320, 400, etc.

To avoid confusion, only one GSA diameter should be used per timber frame.

For girders with parallel beams, it often makes sense to execute the first 1-2 struts in hardwood. These are around 50% more efficient than softwood versions. When using BauBuche struts, a calculated tensile stress of 18 N/mm² is also recommended as an initial estimation. Higher efficiency factors in the struts are possible. However, these require mostly hardwood reinforcements in the beams.

Girder width

In the ideal case, the beams are at least 20 mm wider than the largest strut and have as square a cross section as possible.

Upper beam

In most cases, the upper beam must be measured with the gross cross-section under pressure with flexion. The threaded rods only lead to a weakening if the flexural tension from the support moment cannot be overridden by the normal force.

Lower beam

For the lower beam, the verifications are to be performed for each joint at the net cross section.

For this, the calculated beam width per 80 mm brace width is to be reduced to 22 mm.

Example:

Beam 400/400

Strut A 240/240

Strut B 320/240 → 320/80 = 4

Beam cross-section for verification N+M:

400-4*22 = 312 wide / 400 high

Modelling

Struts

An articulated model of the struts is permitted when using the GSA technology. The requirements for this are outlined in the Basics.

Reduction according to Norm SIA 265 clause 5.3.6.2.2 is not required.

Rigidity

For timber frames in softwood, the struts may also be modelled in the area of the joint with the gross cross section of the wood.

Beams

If the beams are under load between the joints, the resultant stresses are to be taken into account.

Centring

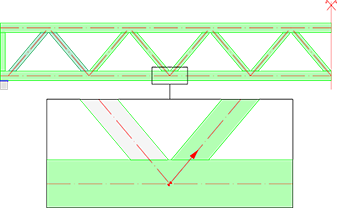

Centring of the bar axis in a joint is desirable. In accordance with Norm SIA 265, the simplified calculation is made as per clause 5.3.6.1.2 if the axes of the diagonals are still within the faces of the continuous beam. However, the stresses resulting from local force transmissions must be taken into account.

Poster GSA-FW

Tender text GSA-FW (german)